- Contact Person : Ms. Zhang Chin

- Company Name : Xinxiang Lier Filter Technology Co., Ltd.

- Tel : 86-0373-2513965

- Fax : 86-0373-3512383

- Address : Henan,Xinxiang,200 Meters East To Zhoucun, Wangcun Town, Muye Area

- Country/Region : China

- Zip : 453000

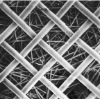

Sintered Metal Fiber Felt

Detailed Product Description

Sintered metal fiber felt is composed of steel fiber mesh sintering together. Then it still have feature of web and porous construction, high strength, high stable construction in high temperature vacuum oven, it also has higher porosity, large specific area, and uniform distribution. These advantages made it have an ideal material of heat-resistant, corrosion-resistant and high precision. These reusable, high quality filters are ideal for liquid filtration and gas filter application.

Main Application:

1. Polyester melt purification in chemical fiber and membrane industries.

2. High temperature filtration and corrosion liquid filtration in petroleum industry.

3. Hydraulic fuel and lubrication oil filtration in mechanical equipment.

4. Liquid purification in pharmaceutical , biological and beverage industries.

Performance and Advantages:

1. High dirt holding capacity, high filtering accuracy, longer on stream life.

2. Corrosion resistance of nitric acid, alkali, and organic solvent proof. It can be used for a long period of service in the temperature of 600.

3. High porosity and excellent permeability which results in low pressure drop and large flow.

4. Pleatable, provide a large filter area pr unit of volume, and they can be welded and machined.

5. Cleanable, can be reused numerous times.

Product Technical Criteria and Deviation

Specification Um(c) | Filter rating Um(c) | Bubble point pressure (pa) | Air permeability L/(min.dm²) | Porosity (%) | Dirt holding capacity (mg/cm²) | Thickness (mm) | Breaking tenacity (MPa) | |||||||

Basic | deviation | Basic | deviation | Basic | deviation | Basic | deviation | Basic | deviation | Basic | deviation | |||

5 7 10 15 20 25 30 40 | 4.0-6.0 >6.0-8.0 >8.0-13.0 >13.0-18.0 >18.0-23.0 >23.0-28.0 >28.0-35.0 >35.0-45.0 | 6800 5200 3700 2450 1900 1550 1200 950 | ±10% | 67 63 105 205 280 355 520 670 | ± 20% | 75 76 75 79 80 80 80 78 | ±10% | 2.5 3.8 4.0 6.8 11.5 18.0 22.0 32.0 | ± 20% | 0.30 0.30 0.37 0.40 0.48 0.62 0.63 0.68 | ±10% | 32 36 32 23 23 20 23 26 | ± 20% | |